In the past, the operation of stand pipe actuators was always a critical and dangerous part of the coke oven machinery automation.

Either the operation was done manual or via tools installed on the charging car without real feet back to the automation system.

|

It is not necessary to talk about the high accident risk during manual and not interlocked operation.

But also the operation via the charging car is not free from risks for wrong operations because off missing positive detection from the stand pipe actuator itself.

The new stand pipe automation system AUTOSTANDPIPE, which was developed together with RAG (Ruhrkohle AG) solves the above descript problems in a safe and efficiency manner.

|

|

|

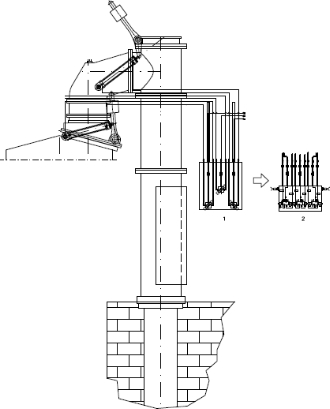

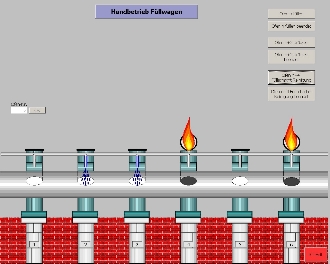

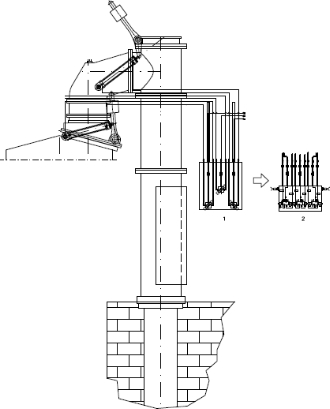

AUTOSTANDPIPE can easily be integrated in existing infrastructures of stand pipe units and automation systems.

It is only necessary that the plant is equipped with pneumatic operated stand pipe actuators.

|

|

|

Instruction

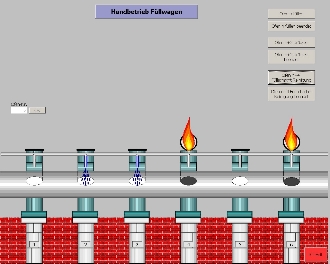

The functions of the automation system AUTOSTANDPIPE can be describe as follows:

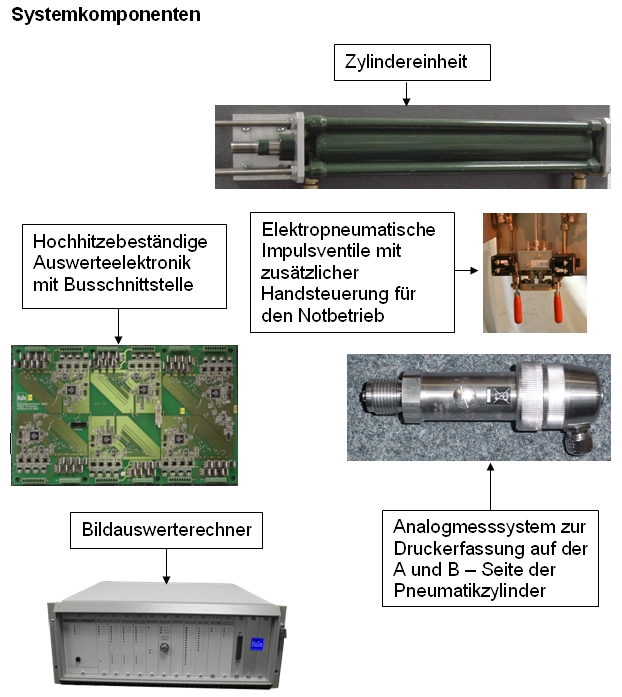

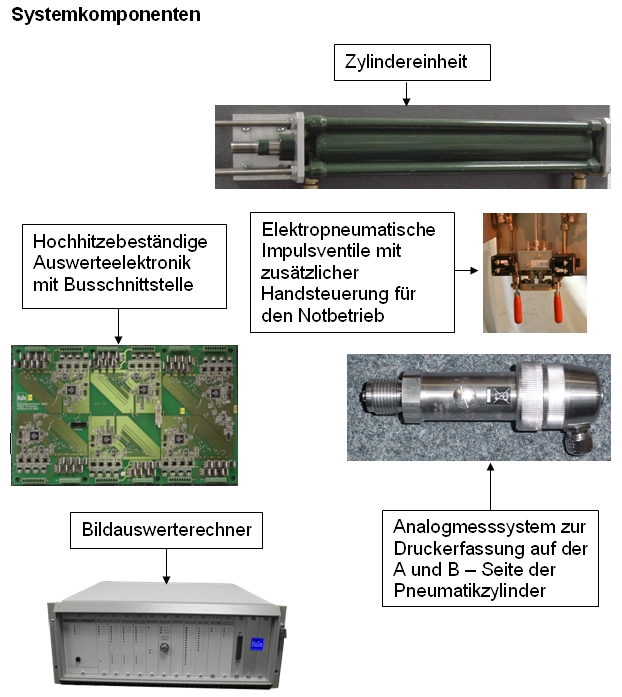

The existing manual valves for the stand pipe actuators have to be replaced by electrical impulse valves.

The new valves only needs an electrical impulse to be set in the required position.

The position will be hold also without power supply. This functionality reduces the internal heat load of the valves and the size of the power supply units.

In additional to the electric function of the valves manual emergency operations are implemented.

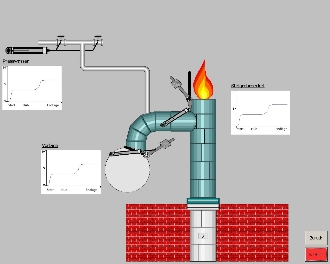

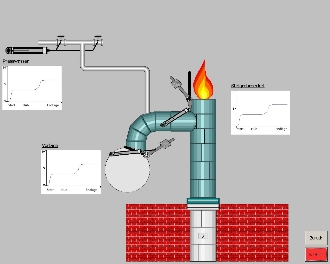

The movement of the cylinder is controlled by an analogical measurement system witch measure the pressure curve in the pipe at both sides of the cylinder.

|

|

|

This analogical measurement system analysis any difference between the actual pressure curves and the master pressure curves. With this method it is not necessary to have any limited switches in the system exposed to high surrounding temperatures.

The system represents a self teaching and flexible automation module. The software allows a continues automatic adjustment to different pneumatic and mechanical conditions of the standpipe system.

The AUTOSTANDPIPE electronic is specially developed for the hot operational area. Up to an ambient temperature of 100°C additional cooling systems are not required.

|

|

|

The data communication is organized by glass fibre optic cables.

One electronic unit can handle and control up to six stand pipe actuators.

|

|

Special camera to detect the flame at the open stand pipe located at the charging car

|

|

To detect the flame at the top of the stand pipe a camera system is linked to the locking chain of the process.

The complex image interpretation module of the camera system is able to differentiate real inflammation and hot gas under night and day conditions.

Two or three camera units can be integrated to the system depending on the chosen production process.

The camera and the housing of the camera are developed specially for the hot temperature.

|

|

|

The weatherproof and air-cooled camera housing is equipped with a heat resistant glass for the camera optic.

The objective of the camera itself is designed in that way to be able to operate through a very small hole without a reduction of quality. This construction allows to install the camera very close to the monitored flame.

Because the camera system is installed at the charging car, only one set is necessary to control and interlock the total battery.

|

|

|

|

Download brochure