Data communcation system

The HuDe data link and communication units are security oriented. The data link is based optional on the following two different types of transmission medium:

- glass fibre optic technology

- HF data radio technology

A safety transmission medium combined with robust software protocol structures forms the stable backbone of the HuDe automation technology.

Optimizing of oven filling (Level Control)

HuDe coal charging systems guarantees a maximal individual oven chamber filling, short filling times and minimized opening periods.

High priority is given to production optimizing and emission protection.

The development is based on a cooperation between Schalker Eisenhütte and KPS Kokereibetriebsgesellschaft Schwelgern GmbH.

Process visualization

The HuDe Software for visualization (HMI human machine interface) allows a realistic reproduction of all sequences of processes.

The HuDe HMI presents detail process information and has a clear representation. The software supports:

- the operating

- the controlling

- and the maintenance activities of the operator.

HuDe Drive control for coke oven machines

The new positioning system for coke oven machines, called "HuDe Drive Control", summarises the previous experiences in the business of positioning and identification technologies to a technical complete solution.

HuDe Drive Control allows an exact positioning.

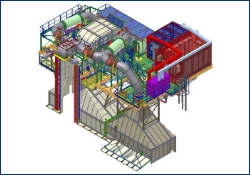

Process automation

The HuDe process automation system in the highest level allows the man less operation of coke oven machines. The differnt HuDe automation levels for modern coke oven machines are:

Level 1:

Over all leading and control system of all coke oven machinery (menless operation)

Level 2:

Interlocking and coordination of the coke oven machinery and service units

Level 3:

Local machinery control and process "visualisation"

The HuDe automation system (Level 1, Level 2, Level 3) can be realisied with different customer specific hardware components.

Stand pipe automation system

In the past, the operation of stand pipe actuators was always a critical and dangerous part of the coke oven machinery automation.

Either the operation was done manual or via tools installed on the charging car without real feet back to the automation system.

HuDe Stamping Control

All users of stamping machines need the patented HuDe Stamping Control System. The HuDe Stamping Control system allows the online monitoring and controlling of all sequences of the stamping process.

The explosion protected sensors are mounted at every stamping pusher. All sensors transmitted their data wireless to the central data analysis unit.