The new positioning system for coke oven machines, called "HuDe Drive Control", summarises the previous experiences in the business of positioning and identification technologies to a technical complete solution.

HuDe Drive Control allows an exact positioning.

| The new Positioning System for coke oven machines |

|

The exact proceeding of coke oven machines and its precise positioning are decisive for the optimisation of the cycle time and the operational safety for the total machinery set.

Also a sufficient location identification system is absolutely necessary.

The new positioning system for coke oven machines, called "HuDe Drive Control", summarizes the previous experiences in the business of positioning and identification technologies to a technical complete solution

|

|

|

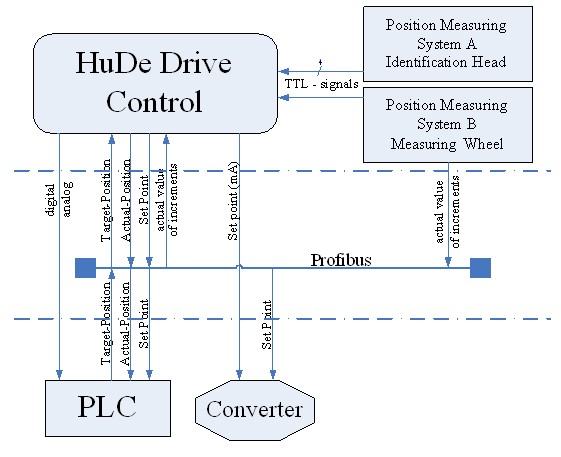

HuDe Drive Control is a self-controlled function unit which fulfils following performance:

- redundant position identify permitted for “cross battery interlocking”

- automatic long travelling controlled by an integrated track calculator

- validation check

- communication to the PLC over standard bus interfaces

All components of the system have been developed especially for operation in coking plant atmosphere and for extremely high environmental temperatures. |

|

The function

The components

Position Targets

A robust, heat resistant, adjustable position target is located to each defined position. The position can be selected as close as possible to the coke oven.

Code reader

The identification code reader contains the finished ends of protected optical fibre cores and two integrated RFID transmitters. The identification code reader can be used up to an environmental temperature of 350 degrees Celsius.

|

|

|

Measuring wheel with incremental encoder

The spring loaded measuring wheel with an implemented encoder is used for continues detection of the travel distance. The measuring wheel is designed for operation on bad track conditions and on twist strengthened machines.

Beside of that function, the system controls the reading of the code reader head by comparing the results of both detection units.

|

|

|

Function and control unit

The function and control unit of the HuDe Drive Control system contains all

hard- and software modules which are required for the automatic

travelling, positioning and position identification of coke oven

machines.

The function and control unit is located in a box inside the electric cabin of the coke oven machine. Additional software tools on existing machine PLC´s are not required.

Interfaces

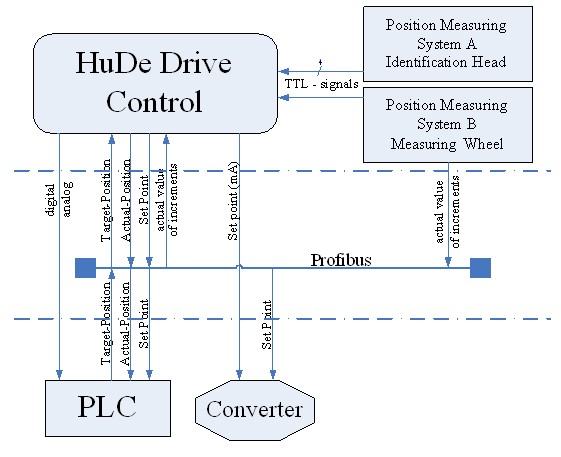

The HuDe Drive Control system communicates with the machine PLC and the long travel equipment via a Profibus interface. (Other interfaces on request)

Alternative digital- and analogue in- and outputs are possible.

|

|

|

The highlights

- Robust system design for using at coke oven batteries under high temperature surroundings

- Positioning target location at the right place where oven camber movements could be compensated

- Redundant Positioning and oven identification

- Bidirectional code reading without support from the measuring wheel or direction signals form the machine PLC

- No PLC-tools needed

- Integrated track calculator

- Reduction of positioning time

- Reduction of cycle time

- Cross Battery Interlocking possible and authorized

|

|

Download brochure